For nearly a decade, many industrial organizations are upgrading their production systems in-line with latest trends in digital technologies like Big Data, Artificial Intelligence (AI) and the Internet of Things (IoT). Leveraging these technologies manufacturing enterprises are implementing Cyber-Physical Production Systems, which digitize enable the digital transformation of production processes, create digital Product Service Systems (PSS) and boost sustainable development practices. In this way, modern factories are implementing novel approaches to manufacturing goods, including intelligent management and maintenance of assets, advanced quality management techniques and flexible PSS design approaches that can effectively address surges in customer demand. The deployment of such advanced production methods and techniques in the production shopfloor is part of the fourth industrial revolution (Industry 4.0), which is destined to improve production excellence based on the development of advanced PSS solutions that leverage cloud services to enable on-demand production.

Nevertheless, Industry 4.0 is not only about improving the effectiveness, agility, speed and cost-efficiency of production processes. Rather the fourth industrial revolution is also about enabling smarter and more customized products, which are tailored to the consumer’s preferences. Industry 4.0 is therefore revolutionizing both products and production processes.

Industry 4.0 and Mass Customization

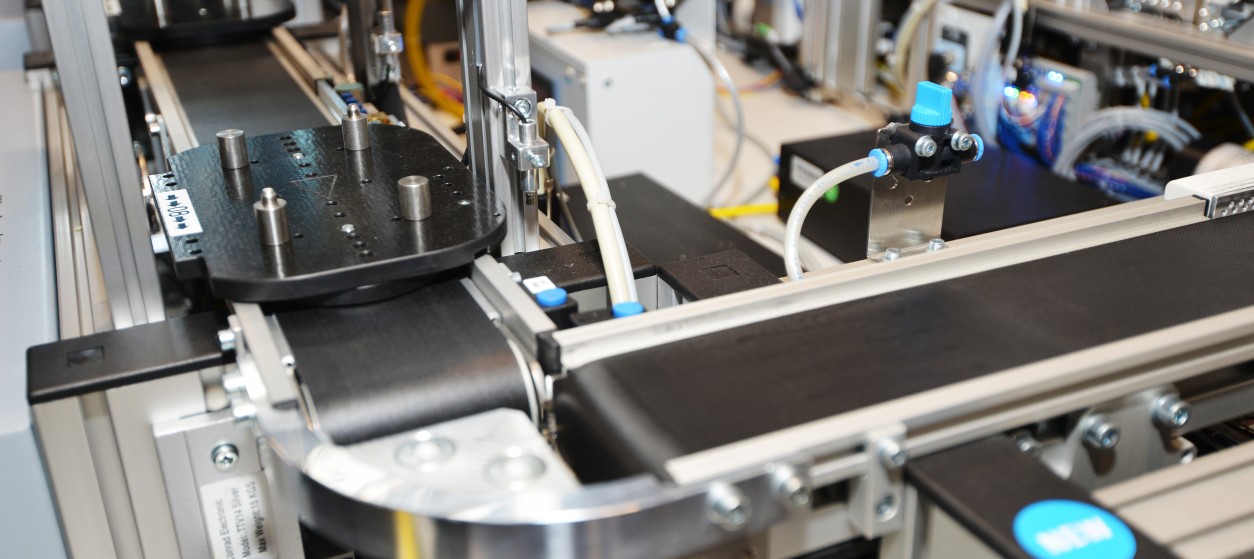

The previous industrial revolution (Industry 3.0) was driven by the introduction of the production line, which enabled massive and cost-effective production of goods (i.e., mass production). The mass production model boosted industrial competitiveness and led to the massive availability of retail products that were held in stock. However, this legacy production model is pushed to its limits, as customers demand more customized products and companies seek more efficient ways to reduce inventory costs and optimize supply chain operations. In this context, Industry 4.0 promises a radical shift from mass production to mass customization leveraging the agility of digitally enhanced production systems such as flexible production lines and digital twins. Specifically, Industry 4.0 changes the conventional Made-to-Stock model to more customized Made-to-Order and Engineering-to-Order models. This means that Industry 4.0 production lines are very efficient in producing multiple variations of a product rather than disposing with a single product configuration. For instance, a flexible robotic cell can automatically produce multiple variations of liquid related products (e.g., variations of a shampoo or perfume), simply by reading a QR code or an RFID (Radio Frequency Identification) tag attached to a customer order.

Digital technologies like Big Data, AI and robotics boost the development of flexible production lines, which facilitate production scheduling, creation of product configurations and management of supply chains in-line with the customers’ expectations. Furthermore, novel approaches like additive manufacturing based on 3D printing are contributing additional flexibility. Based on 3D printers it is nowadays possible to instantly print customized versions of certain products leveraging their digital representations (i.e., digital models of a product).

Another factor that facilitates and amplifies mass customization is the increased used of ecommerce, which leads to an electronic reception of orders in advance of the products’ manufacturing and delivery. Manufacturers have access to digital data about customers’ demands towards optimizing production schedules. They can also access information about customized configurations requested by customers. Leveraging this information, they can also optimize the product customization processes in their flexible production lines.

Industry 5.0: On-Demand Mass Personalization and Everything-as-a-Service

Nowadays, many manufacturers offer customized products based on Industry 4.0 production technologies. However, the scale of the customization is still quite limited. For instance, customers are usually offered with a few configuration options that are pre-defined by the manufacturer. Likewise, in several cases personalization is only possible at a sales point with guidance from some salesperson. Hence, there is still room for providing customized and personalized products at a larger scale. Mass personalization is in-line with the vision of Industry 5.0, the next evolutionary step in industrialization, which will emphasize human-centric products and production processes. Mass personalization in the emerging Industry 5.0 era will have the following characteristics:

- Human centered product configurations: The era of mass personalization will offer ergonomic, human-centered and easy to use interfaces for consumers to define their preferred product configurations.

- On-demand ordering of personalized products: Mass personalization will be offered in-line with the on-demand economy. Consumers will be able to request personalized products regardless of time and their location. It will be possible to ask Siri, Alexa, Hey Google and other voice assistants for personalized products and have them delivered at their homes.

- AI-based Production Lines: Future production lines will be digitally enhanced with advanced AI and other automation technologies to support mass personalization at a reasonable cost. For instance, generative product design techniques will be used to produce automatically and fast all possible alternative bill of materials and production configurations in order to determine the one that matches the customer preferences.

- Flexible and Efficient Supply Chains: Mass personalization will put pressure on future supply chains, as personalized products will ask for increased efficiency in logistics, warehouse management, inventory management and last mile delivery processes. Thus, there will be a need for many data driven optimizations in supply chain management to support the manufacturing and delivery of personalized products within reasonable time limits.

- Personalized Products Marketplace: Product personalization at scale will empower new business actors, such as companies that will focus on the production and delivery of highly customized products at a large scale. Moreover, marketplaces of personalized products will be created. Such marketplace which will offer access to tools and techniques for building personalized product configurations and ordering personalized products.

The ultimate vision of mass personalization is the support of the Everything-as-a-Service (xaas) paradigm, which will permit the production and delivery of any product to any customer regardless of product sophistication, degree of customization, time and location. Xaas solutions are implemented in the cloud, based on on-demand, pay-as-you-go models. In the context of the xaas model, consumers can request anything they want, whenever they want it, without essential constraints in the degree of a product’s personalization. This gives rise to an era where production capabilities and production processes will be limited only by human imagination. Based on xaas services product innovation will become more accessible and more human centric than ever before.

The vision of mass personalization and xaas production models is fantastic, yet very challenging from a technical and organizational viewpoint. It will take several years before any consumer becomes able to order highly personalized products through his/her smartphone. Nevertheless, we are already seeing instances of xaas in cloud computing production, along with a rising interest in personalized products and services. Mass personalization is one of the big themes of the next industrial revolution, which will have a positive impact on human lives and on business competitiveness alike.