The industrial markets have been undergoing rapid changes for decades now. Most manufacturing and logistic units have evolved from low-tech to high-tech, which has significantly improved their efficiency in carrying out labor intensive operations. This evolution has been motivated by various factors such as rising costs, faster product changeovers, and the need to produce a wider spectrum of highly customized products. Towards supporting such evolutionary changes, manufacturing enterprises are turning to advanced automation technology. Nowadays, collaborative robots (cobots) are among the most prominent examples of such disruptive automation technologies.

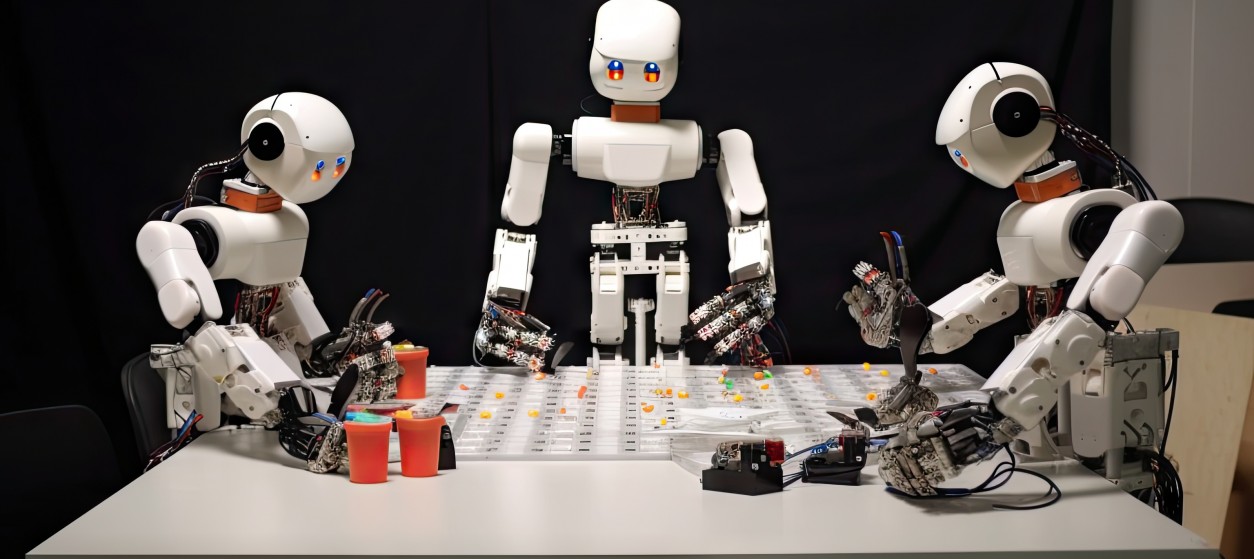

Cobots are industrial robots that can operate safely around humans. They are equipped with an advanced set of sensors, which enable them to perform a wide range of tasks in collaboration with human workers. From a technological perspective, cobots use artificial intelligence algorithms, machine vision and deep learning to adapt to their environment and to ensure their safe collaboration with humans. Cobots will play an instrumental role in the future of manufacturing because they can work alongside humans without any safety hazards. Hence, they can perform repetitive tasks and jobs that are too dangerous for workers, such as welding or handling of dangerous chemicals.

The term cobot was first used in 2013 by the Robotics Industry Association. Cobots are mainly used in the automotive and food industry, yet they are also found in other sectors such as healthcare, education, retail, and logistics. Cobots have been around for a while, but they’re relatively new to the modern world of industrial applications. Nevertheless, the use of cobots is on the rise, as many industrial manufacturers have already adopted or plan to adopt them in the coming years. The interest in cobots is expected to continue as more manufacturers look to automate their production lines with robots that can be paired with humans for tasks that require precision and dexterity. Moving forward, cobots are here to stay and likely to find their way into all sorts of industrial workplaces.

Benefits and Applications of Cobots

Cobots are extremely versatile, which makes it suitable for many different applications i.e., from simple material handling and warehouse management to complex assembly tasks and testing procedures. The most prominent applications of Cobots concern repetitive or hazardous tasks such as:

- Products’ Assembly where robots pick parts and humans guide robots in the assembly process. In most assembly use cases, cobots tend to assist humans in performing repetitive tasks such as picking.

- Quality Inspection where ai robots use deep neural networks to do the inspection and humans help them classify products in cases of uncertainty. Likewise, cobots are also used in production testing tasks i.e., to test products before they are shipped out to customers.

- Packaging and handling tasks where humans handle products that need special care (e.g., fragile or high value products), while robots take care of other products.

- Repair and maintenance tasks, where the repetitive part of the task is assigned to the cobot, while humans focus on more specialized tasks.

One of the most important benefits of cobots in the above listed applications is that they allow workers to focus on more complex tasks instead of the simple ones that are undertaken by machines. In principle, cobots are designed to perform simple and predictable tasks such as picking objects up from a conveyor belt and sorting items in a bin. These tasks would otherwise be performed by unskilled workers. Cobots are not typically designed for complex, non-repetitive tasks like those performed by skilled workers or engineers. Overall, cobots enable manufacturing workers to do more interesting and meaningful work, which leads to higher productivity and improved well-being for employees.

Another benefit of cobots lies in their ability to improve worker safety by reducing the risk of injuries caused by repetitive tasks or lifting heavy objects. There benefits can be attained with minimal training, as most cobots can be easily operated by non-experts.

Examples of Cobot’s Benefits in Various Industries

As already outlined, cobots are used in various industries including:

- Automotive Industry: In the automotive industry cobots work with humans to build cars. Cobots are typically employed for tasks associated with painting, welding, polishing, or assembling vehicles. They are also used to perform repetitive tasks that are dangerous for humans to do, such as lifting heavy objects or working with sharp edges. The benefits of using cobots in the automotive industry include: (i) Increased safety as cobots can only do what they have been programmed to do and hence won’t make human errors like forgetting to shut off a machine or not following safety procedures; (ii) Improved productivity given that cobots work more quickly than human and therefore they get more done in less time; (iii) Improved quality control – since there are no human errors and the same identical result will be produced every time the cobot is used.

- Food Industry: In the food industry, cobots are used in packaging lines where they perform repetitive tasks such as placing items into boxes or wrapping them up with plastic wrap or foil. This saves money and time by making production more efficient, while keeping products safe from contamination. Moreover, cobots allow workers to focus on higher value activities, while robots take care of low-level ones such as packing boxes or sorting fruits and vegetables into different types using industrial robot arms instead of human labour.

Despite the rapid evolution of robotics technology many cobots are still expensive to buy and run. However, manufacturers who deploy cobots can expect a productivity increase of around 30%. Moreover, they can achieve increased safety due to reduction of human errors. Cobots have also proven to be much more compatible than traditional industrial robots, which makes them more suitable for moderate to large-sized manufacturing lines. With the right technology integration, cobots could soon replace certain line functions and enable manufacturers to adapt to changes in production processes and fluctuations in customer demand.