The fourth industrial revolution, also known as Industry 4.0, brought about a significant transformation in the manufacturing landscape. It introduced automation, data exchange, and cyber-physical systems to revolutionize factories and industrial processes. But now, a new era is dawning upon us, known as Industry 5.0. Industry 5.0 is an evolution (i.e., industry evolution tech) of the Industry 4.0 model in directions characterized by the seamless integration of advanced manufacturing solutions with the human workforce towards empowering workers and fostering innovation like never before. Industrial enterprises had better explore how Industry 5.0 trends are reshaping the industrial landscape, particularly through advanced manufacturing solutions and smart factory innovations.

Understanding The Essence of Industry 5.0

Industry 5.0 represents a paradigm shift that acknowledges the importance of human involvement in industrial processes. While industry 4.0 focused on automation and machine-to-machine communication, industry 5.0 emphasizes collaboration between humans and machines. This collaboration creates a symbiotic relationship that maximizes the strengths of both humans and machines, driving innovation, efficiency, and productivity to new heights. From a technological perspective, Industry 5.0 is empowered by more or less the same technological enablers as Industry 4.0, including for example Big Data, Artificial Intelligence (AI), Augmented Reality and the Industrial Internet of Things (IIoT). Nevertheless, from a human user perspective, Industry 5.0 solutions can adapt to the needs and preferences of the users’, rather than expecting them to adapt to the operations of the machines. Hence, Industry 4.0 and Industry 5.0 have common use cases in areas like quality inspection, predictive maintenance, and automation flexibility. In all these use cases Industry 5.0 achieve improved users’ satisfaction when compared to their Industry 4.0 counterparts. Likewise, Industry 5.0 technologies include paradigms that foster human machine collaboration such as various human-centered AI paradigms like active machine learning and human robot collaboration.

Empowering Human Workers with Advanced Manufacturing Solutions

As already outlined, one of the key aspects of Industry 5.0 technologies and solutions is the empowerment of human workers through advanced manufacturing solutions. These solutions leverage cutting-edge technologies such as machine learning, artificial intelligence, and edge computing to augment human capabilities and enhance productivity. Let’s delve into some specific examples:

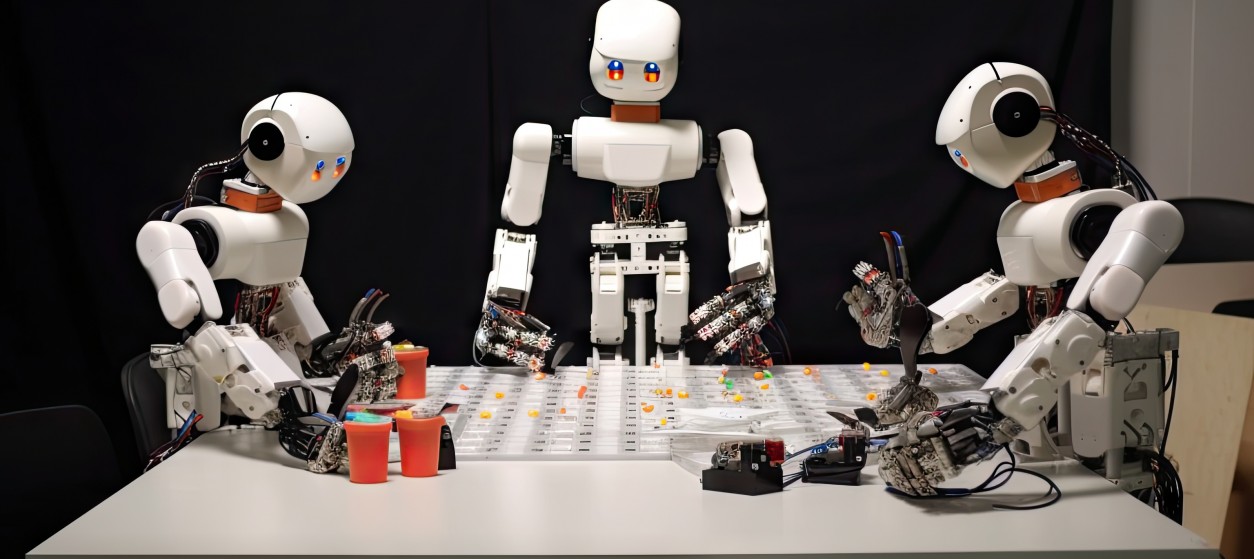

- Collaborative Robots (Cobots): Collaborative robots, or cobots, are designed to work alongside human workers, assisting them in tedious or physically demanding tasks. Unlike traditional industrial robots that operate in isolation, cobots are equipped with advanced sensors and machine-learning algorithms that enable them to respond to human presence, making them safe and efficient collaborators. Cobots not only reduce the physical burden on workers but also allow them to focus on more creative and value-added tasks, unlocking greater potential for innovation.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies have gained significant traction in Industry 5.0. By overlaying digital information in the real world, AR assists workers in completing complex tasks with precision and efficiency. For example, AR-powered smart glasses can provide workers with real-time instructions or virtual models, guiding them through intricate assembly processes. VR, on the other hand, enables immersive training experiences, allowing workers to simulate challenging scenarios without the need for physical equipment or risking accidents. These technologies enhance worker skills and help minimize errors and downtime. As such they lead to substantial cost savings.

- IIoT and Edge Computing: Industry 5.0 leverages the power of the Industrial Internet of Things (IIoT) and edge computing to enable real-time monitoring and control of industrial processes. IIoT sensors collect vast amounts of data from machinery, products, and workers, providing valuable insights into productivity, quality, and safety. Edge computing brings computation and analytics closer to the data source, allowing for quick decision-making and reducing latency. Together, IIoT and edge computing enable human-centered use cases such as predictive maintenance, optimization of manufacturing workflows, as well as worker safety use cases that can proactively identify and mitigate potential issues.

Smart Factory Innovations in Industry 5.0

In addition to empowering workers, Industry 5.0 also relies on smart factory innovations and intelligent factory systems to drive efficiency, sustainability, and flexibility. Let’s explore some of these innovations:

- Digital Twins: Digital twins are virtual replicas of physical assets, processes, or systems. They combine real-time data from sensors with advanced analytics, to s allow manufacturers to monitor, simulate, and optimize their operations in a virtual environment. For example, a digital twin of a production line can be used to identify bottlenecks, optimize equipment utilization, and predict maintenance needs, leading to improved overall equipment effectiveness (OEE) and reduced downtime. In the context of Industry 5.0, digital twins are enhanced with information about the users’ context in order to produce human-centered simulations and determine the operations that maximize workers’ satisfaction.

- Blockchain in Supply Chain Management: Blockchain technology is revolutionizing supply chain management in Industry 5.0 by providing transparency, traceability, and security. Based on distributed ledgers and cryptographic algorithms, blockchain ensures the integrity of transactions and prevents tampering. Manufacturers can utilize blockchain to track the provenance of raw materials, verify product authenticity, and streamline supplier collaboration. This not only enhances trust among stakeholders but also enables more sustainable and ethical supply chains. Trust is a crucial element of human-centered operations in the Industry 5.0 era: Users are not typically willing to use systems like AI unless they can trust their outcomes, which asks for trustworthy data management.

- User-Centric Data Analytics for Continuous Improvement: In Industry 5.0, data is the fuel that drives continuous improvement. Advanced data analytics techniques, such as machine learning and predictive modeling, allow manufacturers to gain valuable insights from the vast amount of data generated by industrial processes. These insights enable predictive maintenance, quality control, demand forecasting, and process optimization. Based on these analytics capabilities and information about the workers’ profile, manufacturers can make informed, worker-centric decisions to enhance efficiency and product quality.

Overall, Industry 5.0 ushers in a new era of industrial transformation tech, human-centered tech, and human-centered industrial applications (i.e., Industrial Applications 5.0), where machines and humans collaborate synergistically to achieve remarkable levels of innovation, efficiency, and sustainability. Advanced manufacturing solutions, such as cobots, AR/VR, and IIoT, empower humans by augmenting their capabilities, fostering safer and more productive work environments, as well as a new wave of connected industry innovations. At the same time, various smart factory innovations enable manufacturers to optimize their operations and drive continuous improvement and the future of industrial applications. As we embrace Industry 5.0, businesses must invest in cutting-edge technologies and facilitate a seamless integration of humans and machines. This will be key for transforming next-gen manufacturing processes into hubs of innovation and excellence.

Good point, makes a sence especially when one is experienced in the topic. So keep righting and share your thoughts and experiences.

I like this website too:

נערות ליווי בתל אביב