Following the COVID19 pandemic outbreak, most enterprises around the world are witnessing the consequences of global supply chain disruptions. From cars to white appliances, many products are less readily available. Hence, consumers must wait for significant amounts of time prior to getting and using the products that they order. The situation is particularly challenging in specific sectors like the high-tech industry which is facing a major shortage of chips. This shortage is affecting the production of high-tech products worldwide, ranging from computers and laptops to modern automotive vehicles. Experts predict that this disruption could last up to two more years, which means that it will take significant time prior to returning to a production normality.

This major supply-chain disruption is largely due to the COVID19 pandemic and its consequences in areas like employment and availability of equipment. To cut a long story short, COVID19 has disrupted the operation of conventional supply chains, while challenging the production capacity of many manufacturers. At the same time, the industry is witnessing shortages in manufacturing workers, equipment, and warehouse space, which makes the effects of the original disruptions much worse. Specifically, as soon as lockdowns were waived, manufacturers were faced with a booming demand. The latter cannot be fulfilled given pre-existing disruptions, inadequate numbers of employees and limited warehouse space that leads to inventory shortages. By and large, despite the gradual lifting of COVID19 measures, manufacturers are having hard times to recover the operations of their supply chains. In this context, supply chain stakeholders are looking into novel and effective approaches for coping with large scale disruptions. Such approaches are important not only for coping with the implications of COVID19, but also for preparing for future disruptions.

Causes of Large-Scale Supply Chain Disruptions

This time supply chain disruptions were caused due to a large-scale healthcare crisis. Nevertheless, there are many other factors that can cause significant disruptions to global supply chains, including:

- Climatic factors, like abnormal heat waves and natural disasters (e.g., earthquakes, floods). Such disasters can have short or medium terms efforts on the manufacturing, shipment, and inventory processes in certain geographical locations.

- Geopolitical conditions, like changes in the status quo of national or regional governments, as well as decisions of geopolitical interest. This was evident during the pandemic, when many countries factored geographic criteria in their supply chain decisions. For instance, certain manufacturers opted to prioritize orders from countries where they maintain their industrial plants. Similarly, many countries declared their intentions to reduce their exposure to certain national or regional supply chains.

- Economic factors, such as changes in interest rates, Gross Domestic Product (GDP) fluctuations, surges in demand about products, as well as variability in liquidity and commodities. Logistics and supply chain management operations are largely money driven and as such susceptible to changes in economic factors.

- Cyber conditions, including cyber-security incidents, data breaches and changing in supply chain technologies. In recent years, supply chain management is mainly about managing information based on digital technologies. Therefore, digital disruptions can lead to supply chain disruptions as well.

In this context, one cannot rule out future disruptions in the global supply chain. Rather than addressing these disruptions after they occur (i.e., in a reactive fashion), manufacturers and other supply chain stakeholders had better invest in their preparedness to cope with them. In this direction, supply chain actors can benefit from best practices and lessons learnt during the COVID19 pandemic.

Building Resilient Supply Chains for the Present and the Future

During the COVID19 period, many manufacturing enterprises and other supply chain actors developed effective, agile, and fast responses to supply chain disruptions. To this end, they employed one or more of the following measures:

- Development of Richer and Automated Supply Chain Directories: The development of catalogues of supply chain information (e.g., products, parts, suppliers) boosts the automation and flexibility of processes like supply/demand matching. They can also facilitate the discovery of products and parts subject to a broader range of criteria, including the geographic location of the manufacturer and supply chain performance parameters (e.g., delivery capacity, delivery times and costs).

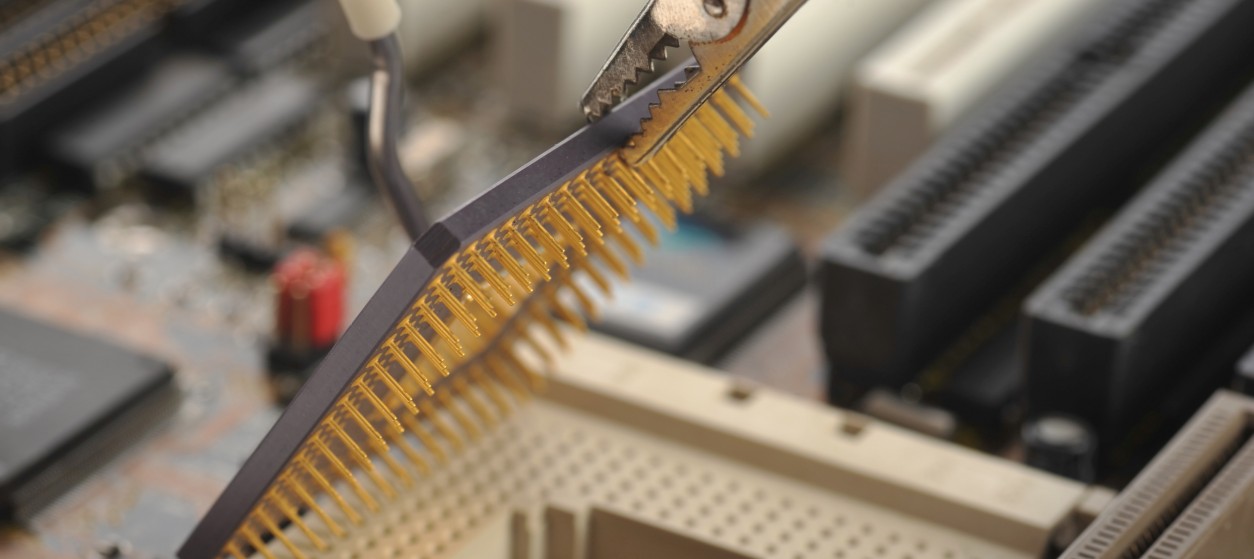

- Employment of On-Demand Manufacturing and Manufacturing as a Service: During the COVID19 pandemic, many supply chain actors employed Additive Manufacturing (AM) to accelerate access to manufacturing parts or even to entire products. Specifically, AM made it possible to print some parts in the production facilities that needed them, rather than ordering them and waiting to be shipped. In cases where a digital model of the product was available, this AM approach ended up accelerating production and supply chain management processes. Overall, AM enabled a novel manufacturing as a service paradigm in the global supply chain.

- Increasing Supply Chain Security and Trust: Many enterprises invested in the cybersecurity of their digital supply chains, as a means of enabling resilient and trusted exchange of information across the different stakeholders. Such increased security and trust were key prerequisites for supporting some of the previously listed processes like the security exchange of digital models in the context of manufacturing as a service.

- Proactive Risk Analysis and Risk Assessments: To ensure early preparedness and develop a proactive response to potential disruptions, supply chain stakeholders had to proactively address their disruption risks. Likewise, they were able to specify and implement mitigation actions for the risk with the highest likelihood and impact.

- Business Continuity Planning: The most effective manufacturing and supply chain enterprises develop effective business continuity plans, which enable them to operate with reduced resources under adverse conditions. As a prominent example, during the COVID19 pandemic, effective enterprises were able to operate based on a reduced workforce given social distancing measures, employees’ infections and other COVID19 constraints. Best in class manufacturers managed to operate at 80%-90% of their production capacity, while some of their competitors had to shut down their factories. In this way, effective enterprises developed a competitive advantage that set them apart from their competitors.

Overall, the COVID19 pandemic highlighted the importance of novel, agile and responsive methods for supply chain management, supply chain logistics, and logistics management. It also indicated novel ways for supply chain integration with business continuity practices. Building on these best practices, organizations can develop their effective response to future supply chain disruptions.