Manufacturing as a Service (MaaS) is a revolutionary concept that is transforming the way businesses approach manufacturing and production operations. Specifically, MaaS enables companies to outsource their production processes to third-party providers, allowing them to focus on their core competencies. This shift has been made possible by the emergence of various new technologies that have streamlined and improved manufacturing processes. Understanding and applying MaaS is largely about mastering, integrating and these technologies that are driving the MaaS revolution.

MaaS Technologies

3D Printing

3D printing, also known as additive manufacturing, has been a game-changer for the manufacturing industry. This technology allows for the creation of complex, customized parts with minimal waste, making it perfect for low-volume, high-mix production. 3D printing empowers companies to offer MaaS services through printing parts or entire products. Based on such printing processes, MaaS providers can offer rapid prototyping and on-demand production services, reducing lead times and allowing businesses to bring their products to market faster. Key to the proper operation of MaaS services based on 3D Printing is the deployment and use of trusted networks that enable the secure sharing of digital models about products and parts. Such digital models comprise critical intellectual property and must be therefore protected against data breaches and other cybersecurity attacks.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) refers to networks of connected devices and sensors that collect, analyze, and exchange data in real-time. This technology enables MaaS providers to monitor and optimize their production processes, ensuring high-quality products and efficient operations. In practice, an IIoT network enables the remote collection and analysis of data from the manufacturing shopfloor to drive optimizations in production operations. For instance, IIoT uses sensor data to enable predictive maintenance that reduces downtime and minimizes disruptions in manufacturing processes. Based on IIoT, these optimizations can take place from remote and as a service based on the MaaS paradigm.

Artificial Intelligence (AI) and Machine Learning (ML)

Artificial intelligence and machine learning technologies revolutionize the manufacturing industry by automating various tasks and processes. MaaS providers can leverage these technologies to improve their production efficiency, reduce waste, and optimize resource utilization. AI-powered algorithms can also be used to perform BigData analytics towards enabling better decision-making and continuous improvement. In the scope of the MaaS paradigm, AI and ML technologies enable on demand analysis of production data towards identifying optimizations and providing prescriptive recommendations to production companies.

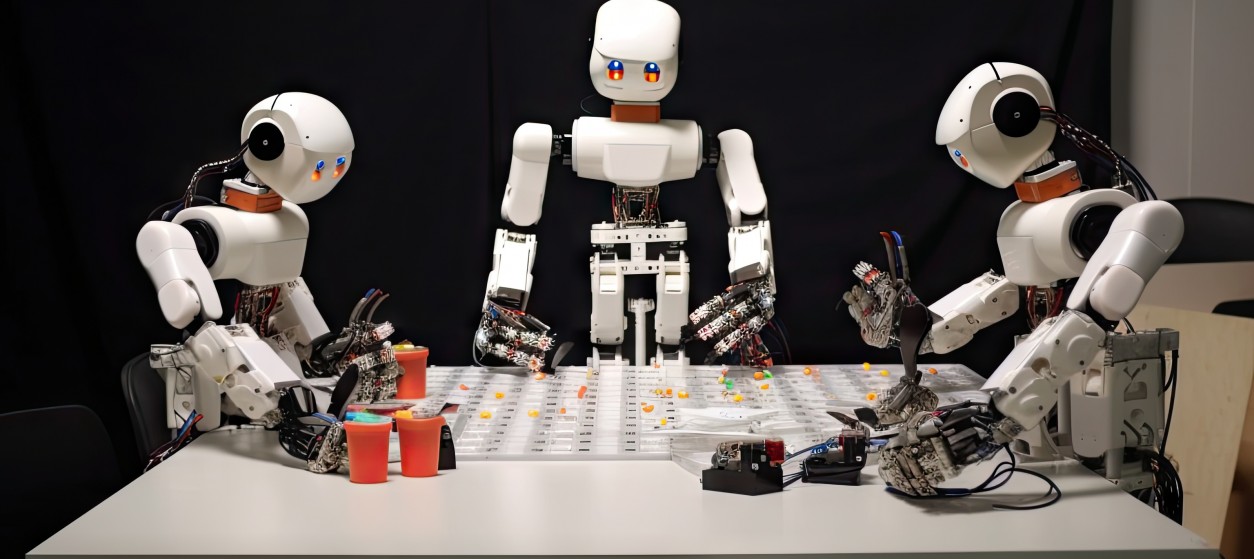

Robotics and Automation

Robots and automated systems play a crucial role in the MaaS ecosystem, as they enable providers to scale their operations and maintain consistent quality. From pick-and-place robots to advanced collaborative robots (cobots) that work alongside humans, these technologies have significantly increased the efficiency and flexibility of manufacturing processes. Automation also helps MaaS providers reduce labor costs and improve worker safety. Furthermore, industrial robots enable MaaS providers to scale-up manufacturing automation in order to offer their MaaS services more effectively.

Cloud Computing and Software as a Service (SaaS)

Cloud computing and SaaS platforms have made it easier than ever for MaaS providers to manage their operations and collaborate with clients. These technologies enable seamless data sharing and real-time communication between different stakeholders, streamlining the entire manufacturing process. Furthermore, cloud-based platforms provide MaaS providers with scalable and cost-effective solutions for managing their IT infrastructure. Specifically, MaaS providers take advantage of the scalability, capacity and quality of service of cloud manufacturing in order to integrate and manage large amounts of data as a service. When needed, cloud based MaaS solutions can be combined with edge computing components to enable reduced latency and offer increased data protection.

Augmented Reality (AR) and Virtual Reality (VR)

AR and VR technologies have found numerous applications in the manufacturing sector, particularly in the areas of training, maintenance, and design. MaaS providers leverage these technologies to improve their workforce’s skills and ensure that their processes are executed with precision. AR and VR can also be used to visualize and simulate complex manufacturing scenarios, which enables better planning and optimization. Recently, AR technology is also used to provide remote support to manufacturing i.e., to enable a manufacturing support as service paradigm. In this paradigm, equipment manufacturers such as machine builders can provide remote support to technicians at manufacturing sites in order to maintain and repair their machinery.

Popular MaaS Applications and their Benefits

Manufacturing as a Service (MaaS) has several applications that are gradually transforming the manufacturing landscape. Some of these applications include:

- Rapid prototyping: MaaS allows companies to quickly create prototypes of their products, reducing lead times and enabling faster product development.

- On-demand production: MaaS providers can offer on-demand manufacturing services, enabling businesses to produce products as needed, reducing inventory costs and improving responsiveness to market demands.

- Customization and personalization: MaaS enables businesses to create highly customized and personalized products, catering to niche markets and individual customer preferences.

- Localized manufacturing: MaaS platforms can help businesses localize their manufacturing processes, reducing transportation costs and improving supply chain efficiency.

- Small-scale production: MaaS is particularly well-suited for small-scale production runs, allowing businesses to test new products or target specific market segments without significant upfront investments. Instead of employing local production resources, MaaS enables access to manufacturing resources as a service and based on the pay-per-use modality.

Based on these applications Manufacturing as a Service (MaaS) offers numerous benefits to businesses, including:

- Cost savings: MaaS allows companies to access advanced manufacturing technologies without making significant upfront investments. This helps them reduce their capital expenditure.

- Flexibility: MaaS enables businesses to scale production up or down based on demand, which helps them improve their responsiveness to market changes.

- Speed of delivery: MaaS providers often have a wide range of suppliers. This allows businesses to choose local firms for faster delivery times.

- Boosting innovation, customization, and time-to-market: Technologies like 3D printing enable MaaS providers to offer highly customized products and rapid prototyping. Leveraging 3D printing it is possible to reduce time-to-market and to rapidly reconfigure production in response to disruptions.

- Reduced risk: MaaS allows businesses to leverage the expertise of specialized manufacturing providers. This helps them mitigate the risks associated with manufacturing processes.

- Focus on core competencies: By outsourcing manufacturing, businesses can concentrate on their core competencies, such as product development and marketing.

In conclusion, the rise of Manufacturing as a Service is being fueled by a range of innovative technologies that are reshaping the manufacturing landscape. These technologies are enabling MaaS providers to deliver high-quality, cost-effective, and flexible manufacturing solutions to businesses across various industries. As these technologies continue to evolve, we can expect to see even more growth and adoption of MaaS in the coming years.